Monitoring scheme of tube trailer

Introduction:

DeleeTech's sensors and instruments based on the Internet of things can be quickly connected to the cloud to realize the synchronous monitoring of the long pipe trailer and the gas in the pipe by computer and mobile phone. They are suitable for hydrogen, compressed natural gas CNG, oxygen, nitrogen, argon, carbon dioxide, nitrous oxide and other gas media. Multiple parameters can be remotely transmitted to the cloud platform to realize the monitoring of the gas pressure, temperature, gas concentration , etc. Real time monitoring of gas concentration and other data, timely alarm, online security management and operation analysis of cloud, and cloud layout of asset Internet of things are realized. Effectively increased the pressure vessel monitoring efforts, improve the safety of the equipment. The design of the electronic fence function of cloud platform is helpful to the dispatching and operation of long-distance vehicles, reduces the input cost and improves the productivity.

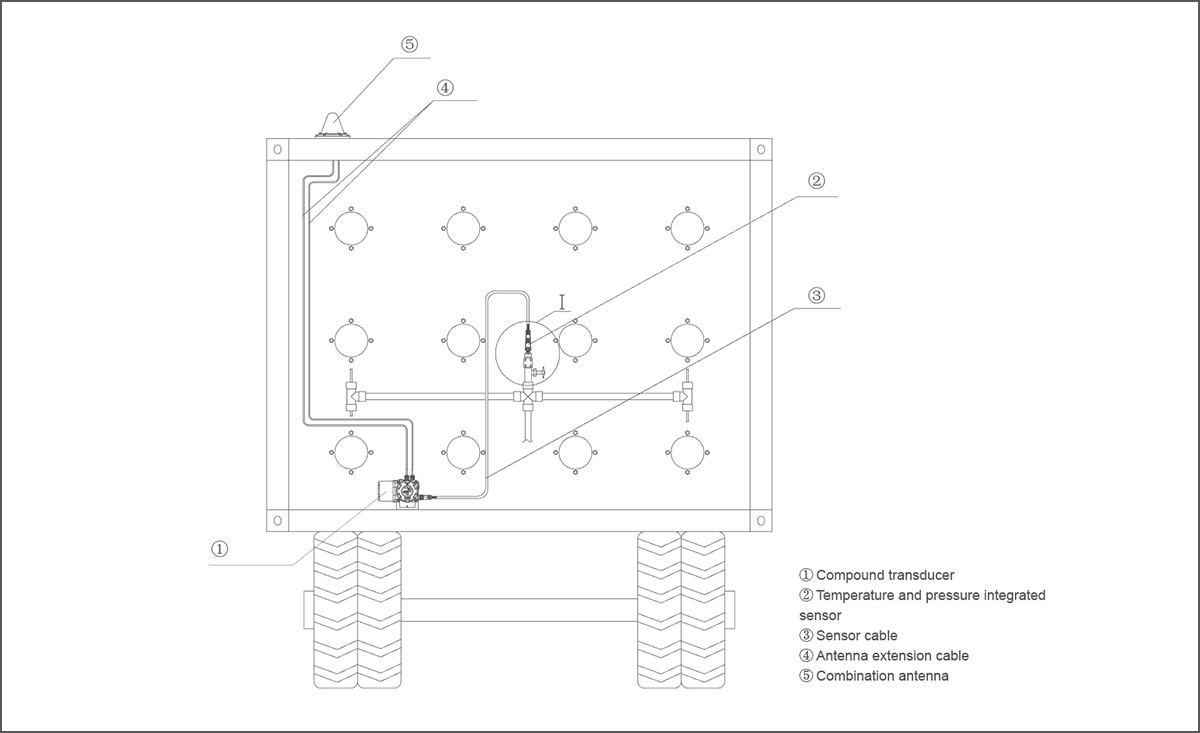

It is recommended to install the following two IOT instruments: Temperature pressure composite transmitter (4G + GPS / BD) DPT8851 and Temperature pressure composite transmitter (4G) DPT8851.

(Click on the picture to view the product introduction)

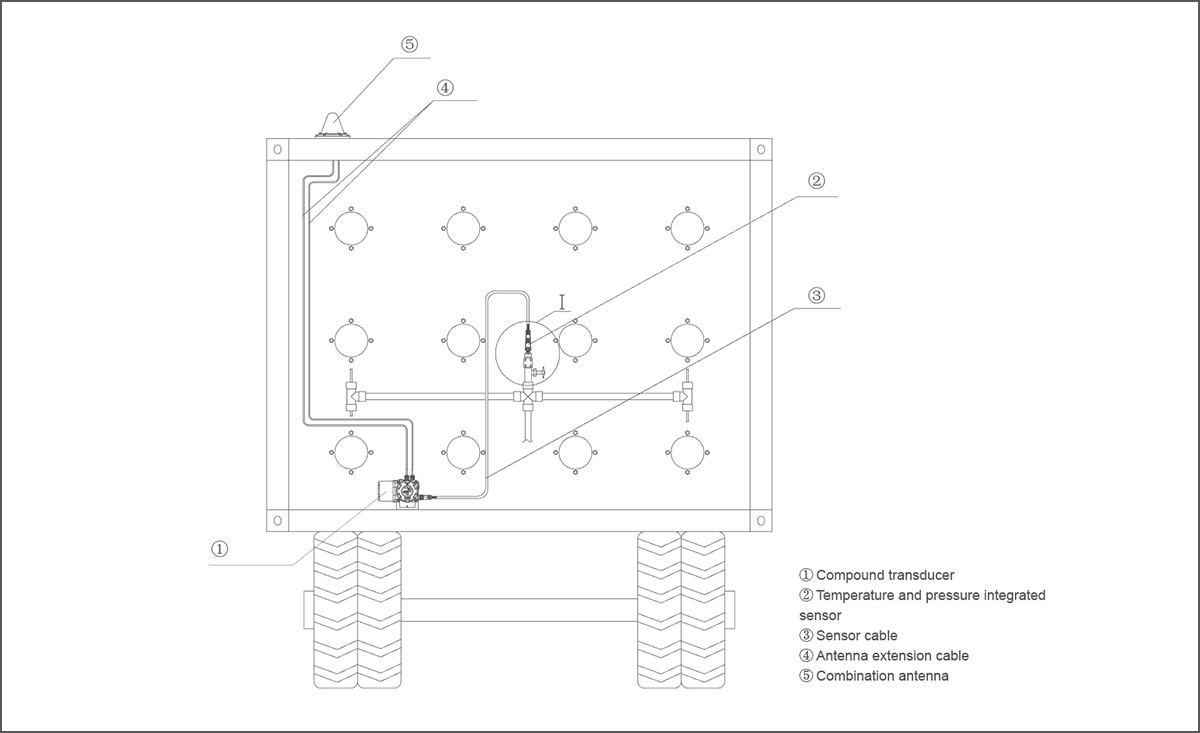

Installation diagram of IOT instrument for long tube Trailer:

Features of the scheme:

■ Suitable for hydrogen, compressed natural gas CNG, oxygen, nitrogen, argon, carbon dioxide, nitrous oxide and other gas media;

■ Integrated temperature and pressure sensor, easy to install;

■ Motion monitoring, collision, tilt alarm;

■ Optional gas leakage monitoring;

■ Built-in RTC clock,set data reporting time;

■ GPS and big dipper two positioning modes;

■ Support national and global roaming;

■ Real-time report and cached report two data uplink methods, choose three ways of periodic reporting, manual triggering reporting and alarm triggering reporting.

■ Parameters can be set locally and in the cloud, and the software continuously upgraded;

■ Power supply: low power consumption battery; large battery capacity and long life;

■ Intrinsically safe explosion-proof design(Ex ia ⅡC T4 Ga), feel safe;

■ IP67 protection grade meets the requirements of harsh working conditions.

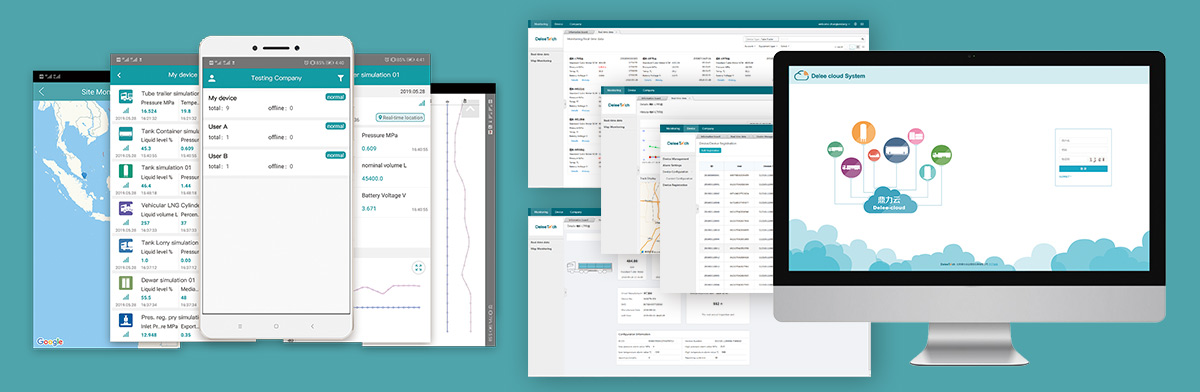

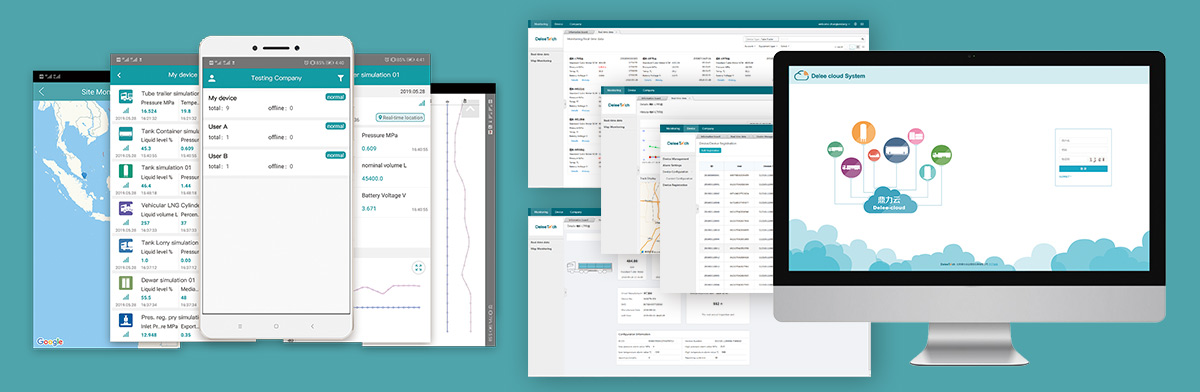

Cloud Platform Intelligence Control System:

Features of Mobile APP Client:

■ To view the information of liquid level, pressure, temperature, location, consumption rate and available time of tanks, liquid tankers, tank containers, cylinders, tube trailers, vehicular LNG cylinders, etc.

■ To view the temperature and pressure of the pipelines, such as gasification, pressure adjustment and so on

■ To view the instantaneous flow rate and accumulative flow of the flowmeter

■ Real time push and reminding of liquid level, pressure, temperature, battery voltage alert information

■ Shows the distribution of all the equipment belong to the company and the real time site location in the map

■ Historical data query, changes in level, pressure, temperature, gas consumption and so on over the past period of time

■ Charging statistics, reflect charging quantities, time points and other information in a period.

Features of PC end software:

■ To view the information of liquid level, pressure, temperature, location, consumption rate and available time of tanks, liquid tankers, tank containers, cylinders, tube trailers, vehicular LNG cylinders, etc., sheet and chart dual-mode display, more intuitive monitoring

■ Shows the distribution of all the equipment and sites belong to the company in the map

■ To view the temperature and pressure of the pipelines, such as gasification, pressure adjustment and so on

■ To view the instantaneous flow rate and accumulative flow of the flowmeter

■ User management: adding, modifying user unit information and authority, assign sites to users

■ Site management: view site name, IMEI number and detail information, add, modify the site name, display site location in the map;

■ Device management: view the detailed parameters of the device, edit and modify device detail information,set liquid level, pressure, temperature, battery voltage alert thresholds, alert clearly and push alert information to mobile APP client.

■ System query: provide changes of device liquid level, pressure, temperature over a past period of time, can be analyzed in data or curve chart, support export data in XLS format, provide the movement track of the device in a certain period of time, provide data query and comparison between two devices, convenient to compare the data from devices produced by different manufacturers.

Typical application cases: